Worldwide of electronics and modern-day innovation, the importance of printed circuit boards (PCBs) can not be overemphasized. These intricate parts form the foundation of practically every electronic tool, from smartphones and computer systems to household home appliances and clinical equipment. A PCB, usually referred to as a motherboard, provides the necessary structure for connecting different electronic elements through conductive tracks etched onto non-conductive substratums. Among the numerous kinds of PCBs, the rigid-flex circuit boards stand apart as an impressive innovation. These are hybrid boards that integrate the very best features of flexible and rigid PCBs, permitting vibrant layouts that can turn and flex without sacrificing architectural honesty. This flexibility makes rigid-flex circuits particularly attractive for applications where area is restricted, such as in smart phones and wearables.

The production of PCBs, especially in high-density interconnect (HDI) setups, has actually developed as the demand for smaller sized, quicker, and more efficient electronics boosts. HDI PCBs include finer lines and spaces, as well as smaller vias, which enable for better part density.

Collaborative ventures with printed circuit manufacturers are vital in guaranteeing that PCB styles change smoothly from conceptual phases to actual items. These manufacturers concentrate on various aspects, consisting of PCB assembly and fabrication. They make use of products like FR-4, a flame-retardant epoxy resin, which is widely concerned for its equilibrium of efficiency and cost-effectiveness. In the realm of high-performance applications, variants such as Rogers material, Megtron 6, and Megtron 7 are regularly used for their remarkable dielectric residential properties and high-frequency performance. As a result, printed motherboard assembly (PCBA) becomes an important action in the process where numerous components are soldered onto the PCB in accurate plans to make certain optimal operation.

Quick turn-around PCB prototyping services have actually gotten appeal as organizations aim to bring their items to market swiftly. This nimble manufacturing approach permits companies to evaluate and validate their styles before devoting to full production runs. Such prototyping is critical in minimizing time-to-market and enables repetitive enhancements based upon first testing outcomes. Suppliers offer flexible choices for both low-volume and high-volume orders to suit diverse manufacturing requirements. Furthermore, with the boosting availability of fast-turn PCB services, the obstacles to prototype development have been dramatically reduced, making it possible for a setting of advancement.

Flexible printed circuit boards (FPCBs) are an additional impressive classification that has amassed focus due to their unique capacities. These boards are created to be lightweight and ultra-thin, supplying the capability to flex, fold, or spin without compromising efficiency.

Thermal administration, for instance, plays an important function in PCB design, particularly in electronic products that operate under high loads. Engineers here must consider materials with excellent thermal conductivity, such as heavy copper PCBs, which aid dissipate warmth successfully.

The understanding of printed circuit board design is fundamental for designers and item programmers. Finding out about different elements such as circuit card assembly, which includes the process of soldering components onto a PCB, can substantially affect completion item's high quality. Reliable design methods make sure that electrical pathways are optimized and that the total design reduces disturbance, consequently enhancing lifespans and efficiency. Furthermore, utilizing tools and software developed for PCB design and simulation can dramatically simplify the design process, permitting developers to quickly alter prototypes based upon testing results.

Variants in PCB types such as 2-layer, 4-layer, and multi-layer boards are each fit to specific applications based on their intricacy and the variety of components that require to be incorporated. Four-layer PCBs offer boosted routing abilities, essential for extra sophisticated electronics. These boards help in managing signal stability and supply enough space to route traces much more successfully, making certain even more dependable performance in whatever from mobile phones to complicated commercial devices.

Contract PCB assembly services have actually ended up being a crucial source for companies lacking the in-house capabilities to deal with complicated assembly processes. These services typically include detailed assistance ranging from design examination to full-blown production, supplying services with the adaptability they require here to satisfy varying needs. By partnering with well-known manufacturers, organizations can utilize knowledge in locations such as HDI designs, microvias, and multilayer PCBs, consequently broadening their product offerings without spending greatly in devices and labor.

Choosing the right products for PCB production is vital, and factors to consider frequently include the ecological requirements appropriate to their use, consisting of UL rankings, such as 94V-0, which concerns fire retardancy. Manufacturers require to remain informed concerning conformity regulations to make certain that their items meet safety and security requirements while additionally doing optimally in their desired application atmospheres.

The assimilation of superhigh frequency (RF) innovation right into PCBs is an additional area seeing boosted relevance, especially with the rise of wireless interaction devices. RF PCBs need to be carefully created, with considerations for resistance control and decreased signal loss due to the high regularities entailed. This expertise needs understanding of RF circuit design and might entail in-depth electro-magnetic simulations as designers work to achieve ideal performance in portable kinds.

As technology continues to progress, manufacturers are significantly check here taking on automation and advanced fabrication processes to enhance efficiency. Technologies such as automated optical assessment (AOI) and surface area place technology (SMT) are currently basic methods, permitting high-speed assembly and regular top quality control. Innovations in PCB manufacturing also reach new materials and techniques, such as the use of embedded innovation where elements are embedded directly within the layers of the PCB, further saving room and improving performance.

To conclude, the printed motherboard sector continuously adapts to altering demands and technological advancements, mirroring the vibrant landscape of electronics. Whether with PCBA, flexible circuits, or fast-turn prototypes, the materials, layouts, and processes related to PCBs are important in shaping the future of electronic devices. Manufacturers that remain at the leading edge of these innovations not just improve their one-upmanship yet likewise enable the development and development of advanced technologies that define modern life. With the ever-increasing complexity of circuits and the need for efficient, high-performance options, the PCB market remains a keystone of technological development, driving the means we interact with tools and ultimately linking our digital and physical globes.

Rider Strong Then & Now!

Rider Strong Then & Now! Tiffany Trump Then & Now!

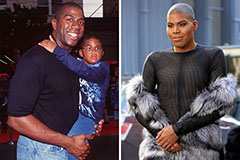

Tiffany Trump Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!